STARRETT NEWS & EVENTS

Precision Measuring Tools & Gages Primer

Basic Requirements for QC

There is a wide range of precision measuring tools and gages that should be considered as basic requirements in a metalworking operation for ensuring good quality control (QC) processes. Most gages are available in analog (mechanical readout) or electronic (digital readout with data collecting capabilities), a key requirement for SPC and measurement documentation. Also, increasingly there are options for convenient wireless electronic tools.

Here is a reference list covering the basic requirements for precision tools:

| 1. Micrometers: In the hands of a skilled operator, the precision micrometer is the most accurate hand-held tool available. When close measurements to 0.0001 of an inch are necessary, the micrometer is the ideal tool for the job because measurement and reading are on the same axis and the anvil end is supported by a strong frame. There are many types of micrometers depending on the application ‒ inside, disc, blade, etc. but outside micrometers are most commonly used. Mechanical, electronic and wireless micrometers are available, including electronic models that are IP67 compliant. For use in harsh shop environments where machine coolant, water, oils, dirt, dust and mist are prevalent, measuring tools with IP67 level protection ensures that precision gage accuracy, performance and functionality will remain fully intact when subjected to these elements. 2. Slide Calipers: Slide calipers are an essential precision measuring tool providing a large measurement range, flexibility and accuracy up to 0.001". These tools typically measure outside, inside, depth, and step dimensions. Full-featured electronic tools, with or without IP67 protection and optional output are available. In addition to common 6”/150mm, 8”/200mm and 12”/300mm tools, large, light carbon fiber models are available as well as more specialized tools with long jaws, alternative contacts and other variations. Dial calipers are very popular and high accuracy, extended range Vernier scale tools are another option. Highly specialized applications may warrant a custom built slide caliper. Wireless models are also available. |

| 3. Height Gages: Height gages are an indispensable instrument for quality control and measure the distance from a reference, such as a surface plate, to some feature of a part -- doing so with exceptional accuracy. Generally a scriber, test indicator, touch probe or CMM-style probe is used to locate the measured feature. 4. Depth Gages: Depth gages are available in varying forms, complexity, cost and accuracy, from the most accurate depth micrometers (electronic, dial and Vernier) to basic rule gages and combination rule gages. 5. Bore Gages: Bore gages are used to check inside diameters of holes, cylinders and pipes. When it comes to measuring holes, especially when there is a large quantity of holes, wireless bore gages can easily collect this data. The technology enables users to measure and collect error-free data to output for Statistical Process Control (SPC) analysis and much more. Also, IP67 compliant models are available. 6. Indicators and Gages: There are several major classes of gages including mechanical dial, electronic display, lever style test and back plunger. Test indicators and dial indicators, in addition to electronic or wireless indicators, are available. Some electronic calipers are IP67 compliant. Indicator requirements can vary widely from checking run-out to measuring tolerances in go/ no-go situations, and they are used in a multitude of applications. It is best to consult a suppler who offers a broad line as well as an extensive range of accessories to configure and position the gage, and if needed, supply a custom engineered indicator solution. 7. Hardness and Surface Testers: Testing the hardness of a material is critical to determine its ability to resist form change, bending, scratching or abrasion. Hardness testers are available in analog and digital bench solutions as well as compact, portable versions. Shore Portable Hardness Testers are targeted for testing materials such as rubber, soft plastics and leather, and versions are also available for the testing of hard plastics such as bowling balls and hard hats. Also, Electronic Durometers for measuring Shore A and Shore D values in a wide variety of soft materials are offered. Ultrasonic Thickness Gages measure the thickness of metallic and non-metallic materials. Coating Thickness Gages use an integrated probe to automatically determine whether the substrate is ferrous or non-ferrous, and then either detects the thickness of non-magnetic coating on a magnetic substrate (ferrous) or the insulating coating on a non-magnetic conductive substrate (non-ferrous). Also, testing the surface roughness is important to identify if a surface is suitable for a particular purpose. |

| 8. Data Collection Systems: With IoT and Industry 4.0 being the omnipresent new paradigm in manufacturing, increasing the speed, amount, and accuracy of data generation is a critical necessity. Precision measurement data acquisition/ collection for quality control applications benefits significantly from wireless and mobile retrieval. Wireless Data Collection systems should be mobile, exceptionally robust with levels of encryption/ protection and suitable for multiple needs ranging from unrestricted distances and gage compatibility, to ease of use and practical integration into automated manufacturing operations. Solutions should dramatically increase productivity, reduce errors, provide full documentation and automate the acquisition process. 9. Squares and Precision Rules, Straight Edges and Parallel: The combination square was invented by The L.S. Starrett Co. founder, Laroy Starrett, in 1877. The combination square is one of the world's most practical and versatile tool inventions ‒ the basic tool for every metalworker. A machinist or layout person can make measurements, use it as a precision rule, measure angles, square, 45° miter, depth or height measurement and even as a scribe. The Starrett Combination Square features high quality workmanship. The square heads are made of cast iron and a photo engraved, hardened and tempered steel rule (blade). This remarkable tool is built to last and is prized by craftsmen. Accurate, Steel Precision Rules are a staple for a metalworking shop and feature photo engraved graduations. Steel Straight Edge versions excel for drawing or scribing straight lines and checking surfaces for straightness. Steel Parallels are indispensable for inspection and layout work or for various setups on drill presses, milling and grinding machine shapers etc. |

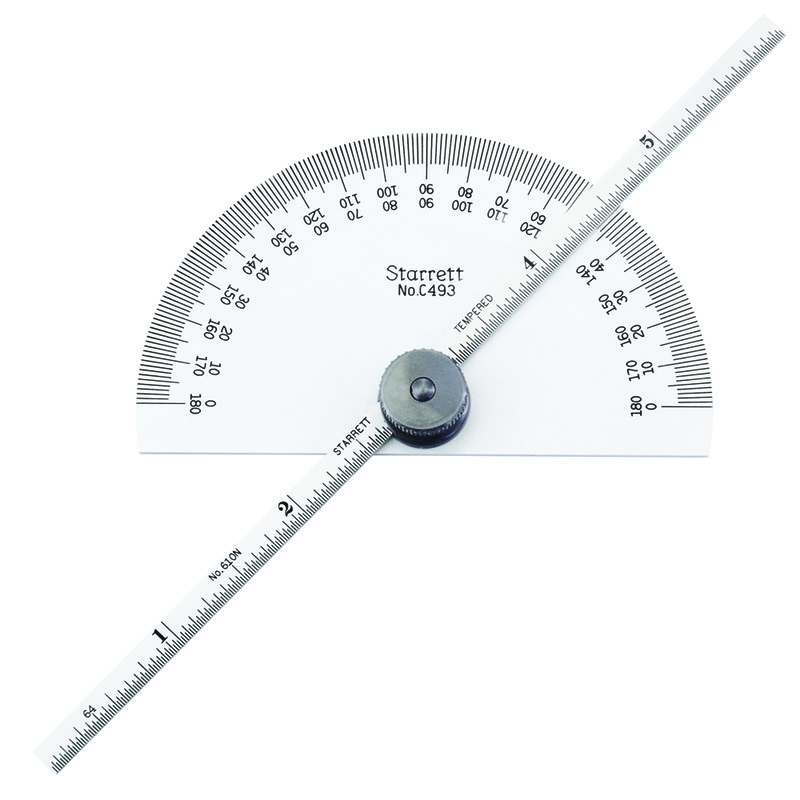

| 10. Protractors and Angle Measurements: A variety of tools are available including ones with sharply graduated 180° scales intersected by a movable blade, a bevel protractor, protractor/ depth gages, special drill point gages and more. 11. Machinist Precision Levels: The efficiency of today's high-speed machinery largely depends on the levelness of the machine set-up. A machinist's level is specially designed to set-up, check and test machinery of all types. 12. Fixed Gage Standards: Fixed Gage Standards are very useful for in-process and final inspection and include a comprehensive choice of standard gages that quickly check dimensions on a variety of workpieces. Products include pin gages, drill gages, sheet and wire gages, center gages, screw pitch gages, radius gages, ball and diameter gages, angle gages, thickness gages and feeler stock. 13. Dividers, Calipers, Trammels: Dividers are an essential tool for measuring, transferring, or marking off distances. Trammel heads are very useful for laying out and scribing circles beyond the capacity of ordinary dividers. Trammels are used for layout, scribing and measuring distances and circles. 14. Other Precision Shop Tools: Tools such as work positioning tools, scribers, punches, vises and layout die lubricant do not measure, but are also an integral part of any shop. |

| Custom GagingThere will always be exceptions to exactly what a shop needs for its QC set-up. Perhaps a unique measurement solution is in order. In these cases, special custom gaging designed and manufactured for a very specific application are an excellent solution when standard products cannot perform. For over 50 years, Starrett has provided special gaging solutions to industries including energy, aerospace, automotive, food packaging, high-technology plastics, medical components and to NASA and over government agencies. StandardsAlso, it is critical to have precision reference standards in any shop's metrology department. Such standards include: Gage Blocks: Precision gage blocks are the primary standards vital to dimensional quality control in the manufacture of parts. The four major characteristics that are necessary for a precision gage block are accuracy, surface finish, wear resistance, dimensional stability and wringability. Other factors are corrosion resistance, hardness, thermal conductivity and coefficient of expansion. Major types that are available today include traditional high-grade steel which are generally used in shop floor environments, tungsten carbide, ceramic and chromium carbide. Surface Plates: Every linear measurement depends on an accurate reference surface from which final dimensions are taken. Precision Granite Surface Plates provide this reference plane for work inspection and layout. A high degree of flatness, overall quality and workmanship also make them ideal bases for mounting mechanical, electronic and optical gaging systems. |