STARRETT NEWS & EVENTS

5 Things You Need To Know about Wireless Gages

Starrett offers insights into why using wireless gages provide QC advantages.

There are many benefits for using wireless gages whether as a gage only or used together with an advanced data collection system -- a process gaining acceptance and momentum for the highest levels of quality control.

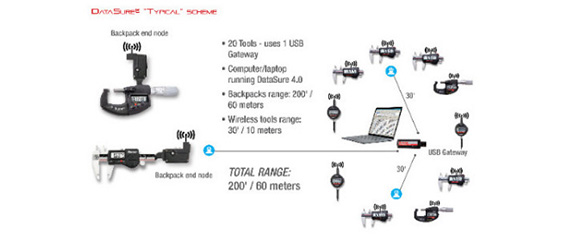

1. First and foremost, wireless measuring tools eliminate the need for bulky and cumbersome hardware such as backpacks and cables which can be safety hazards. Also, by eliminating backpacks and cables, there is less equipment to purchase, so startup costs are decreased, and related maintenance requirements are reduced within the manufacturer’s tool calibration program.

2. Collecting and transmitting measurement data is faster and less error-prone, facilitated simply by measuring and pressing a button to send the data to a mobile phone, tablet, or PC. In this way, operator subjectivity is removed when manually transcribing data. The time spent to manually record the data is no longer a concern. In addition, wireless tools eliminate any recoding measurement errors by manual entries. In simple terms, wireless provides speed, convenience and ease of collecting and storing data.

3. Wireless precision measuring tools are engineered for efficient data collection for a wide range of end uses. Whether it be for International Organization for Standardization (ISO), government, aerospace or medical requirements, or for smaller shops, the need for accurate data is crucial for traceability to demonstrate qualified parts or to trace back any manufacturing errors. Accurate measurement data provides assurance for the end user and insurance for the manufacturer.

4. By using wireless tools and an advanced data collection software system, the data can be efficiently integrated in ERP/ MRP programs. Also, wireless gages promote a cleaner work environment by removing the need for a log journal and pens/pencils, making an ideal setup for Lean Manufacturing.

5. Quality control is the last step when producing manufactured parts, so if a “bad part” slips by, problems can result in the assembly of the final product or the use of the part in the final product. Using wireless precision gages, inspectors can measure with confidence in order to qualify the part. With a simple push of a button, the measurement data is stored for future analysis or for history purposes. The time and money saved by going wireless and implementing a data collection system is incomparable. Digital Calculators are available that can demonstrate that.

With IoT and Industry 4.0 being the omnipresent new paradigm in manufacturing, increasing the speed, amount, and accuracy of data generation is a critical necessity. Precision measurement data acquisition/ collection for quality control applications benefits significantly from wireless and mobile retrieval. Wireless Data Collection systems, such as from Starrett, should be mobile, exceptionally robust with levels of encryption/ protection and suitable for multiple needs ranging from unrestricted distances and gage compatibility, to ease of use and practical integration into automated manufacturing operations. Solutions should dramatically increase productivity, reduce errors, provide full documentation and automate the acquisition process.